Products

USAB SYSTEMS

The upflow anaerobic sludge blanket reactor (UASB) is a single tank process in an anaerobic centralised or decentralized industrial wastewater or blackwater treatment system achieving high removal of organic pollutants.Wastewater enters the reactor from the bottom, and flows upward. A suspended sludge blanket filters and treats the wastewater as the wastewater flows through it. Bacteria living in the sludge break down organic by anaerobic digestion, transforming it into biogas. Solids are also retained by a filtration effect of the blanket. The upflow regime and the motion of the gas bubbles allow mixing without mechanical assistance. Baffles at the top of the reactor allow gases to escape and prevent an outflow of the sludge blanket. As all aerobic treatments, UASB require a post-treatment to remove pathogens, but due to a low removal of nutrients, the effluent water as well as the stabilized sludge can be used in agriculture.

Treatment Process

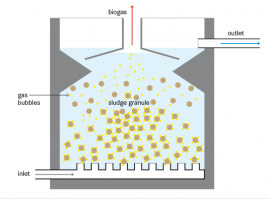

UASB Reactors are constructed out of concrete or another watertight material and can be designed in a circular or rectangular way. Wastewater is pumped from the bottom into thereactor where influent suspended solids and bacterial activity and growth lead to the formation of sludge. The sludge blanket is comprised of microbial granules (1 to 3 mm in diameter), i.e., small agglomerations of microorganisms that, because of their weight, resist being washed out in the upflow. The microorganisms in the sludge layer degrade organic compounds. As a result, gases (methane and carbon dioxide i.e. biogas) are released. The rising bubbles mix the sludgewithout the assistance of any mechanical parts. Upstream velocity and settling speed of thesludge is in equilibrium and forms a locally rather stable, but suspended sludge blanket (SASSE 1998). Sloped walls deflect material that reaches the top of the tank downwards. The clarifiedeffluent is extracted from the top of the tank in an area above the sloped walls. A gas-liquid-solids separator (GLSS) separates the gas from the treated wastewater and the sludge (ROSE 1997, SANIMAS 2005). After several weeks of use, larger granules of sludge form which, in turn, act as filters for smaller particles as the effluent rises through the cushion of sludge. Because of the upflowregime, granule-forming organisms are preferentially accumulated as the others are washed out. Fortunately, these bacteria are also more efficient for biogas production than flocculatedbiomass (WENDLAND 2008).

Design Considerations

Cross-section of an Upflow Anaerobic Sludge Blanket (UASB)reactor. Source: TILLEY et al. (2008)

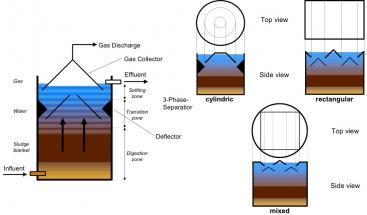

UASB Reactors are constructed out of concrete or another watertight material and can be designed in a circular or rectangular way. Critical elements for the design of UASB reactorsare the influent distribution system, the gas-solids separator, and the effluentwithdrawal design. The gas that rises to the top is collected in a gas collection dome and can be used asenergy (see also use of biogas) for cooking, heating or other, but scrubbing before use is required (UNEP 2004). If the biogas is converted to electricity, the heat produced as a by-product can be reused to heat the reactor, favouringanaerobic digestion.

UASB reactors are separated in three phases: granules, liquid and gas (left). They can be constructed circular or rectangular (right). Source: TBW (2001b)

To maintain the reactor well-mixed and allowing the formation of granules and a good contact of the activesludge blanket and theinfluent sewage, it is critical that the influent is equally distributed in the bottom before moving upwards (see Figure 1). Besides these design requirements, the main influencing parameters are pH, temperature,chemical oxygen demand(COD), volumetric CODloads, HRT and flow, upflow velocity, concentration ofammonia and start-up phase (TBW 2001b).

Advantages

- High reduction of BOD

- Can withstand high organic and hydraulic loading rates

- Low sludge production (and, thus, infrequent desludging required)

- Biogas can be used for energy (but usually first requires scrubbing)

- No aeration system required (thus little energy consumption)

- Effluent is rich in nutrients and can be used for agricultural irrigation

- Low land demand, can be constructed underground and with locally available material

- Reduction of CH4 and CO2 emissions